Features

- 316L Stainless Steel or PTFE Construction

- Compact Design For Fast Response Time

- Choose from Four Housing Sizes

- Accepts Stainless Steel, PTFE and PEL Elements

- Available in Hastelloy, Monel and Etc.

Applications

- Sample Process

- Cooling Water Analysis

- Stack Gas Analyzer Protection

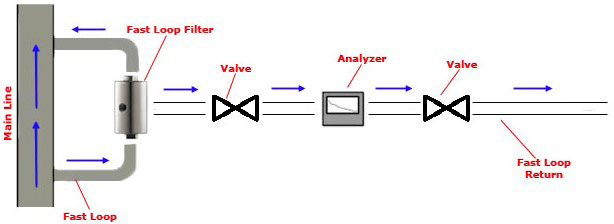

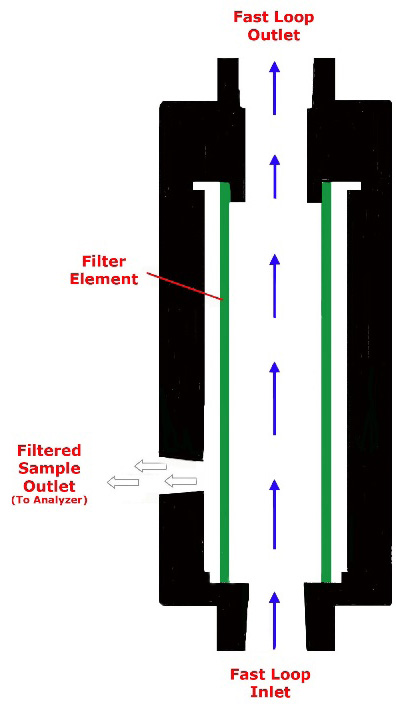

Fast Loop Filters minimize time delay associated with online analyzer sample systems. Our Fast Loop filter solutions go against the wisdom of the traditional three port t-type design by continuously flushing the filter element of heavy contaminates and only filtering the sample stream. This decreases lag time and improves filter life. Axial velocity flushes the bulk contaminants through the filter housing back to the process stream. The sample stream passes through the filter element wall with low flow and radial velocity. The clean side of the sample filter system has very low volume which minimizes lag time. A four to one flow rate is recommended to realize the benefits of prolonged filter element life associated with continuous flushing.

Product Bulletin Download

[table “15” not found /]

Filter Loop Design

Filter Loop Design

The 126IL-3, 127IL-3, 136IL-3 and 146IL-3 are machined from solid bar stock which eliminates welds and provides a 5000 and 1500 PSIG rating respectively.

Our 150IL-3 is constructed of three components to reduce weight, and make element service easier; both end caps are threaded to the filter body. This design reduces the pressure rating to 100 PSIG, but significantly reduces housing mass. Please keep in mind, that we do make Fast Loop style filters in custom sizes and in other materials including PTFE, Monel, Hastelloy, and Inconel.

We also offer the model SG137 and SG147 which provide a Pyrex bowl to visually monitor the process. In these cases, the traditional drain port is used as the inlet, and the traditional inlet is used as the fast loop outlet port. Please consult us for your specific needs.

Maintaining the Filter Element

Our stainless steel filter elements are recommended for fast loop service since they offer a good corrosion resistance and can withstand the continuous-flushing effect. Another advantage of the stainless steel element is the ability to be cleaned by back-flushing. We offer seven standard grades of filtration with a 98% efficiency in the following microns: 01, 03, 10, 25, 50, 100 and 200. Grade 25 (25 micron) is widely used to protect sample flows from visible particulate while grade –03 is recommended for the removal of pipe scale from steam.

PTFE sintered elements are used where sample compatibility is concern and / or PTFE Fast Loop housing is utilized.

SAMPLE ANALYZER STREAM WATER FLOW RATES IN LPM AT 1.5 PSI DROP

[table “” not found /]

For best results, a minimum of a of a 4 to 1 flow rate should be maintained for continuous flushing.

For Example: A model 126IL-3 with SS-12-57-10T (10 micron) will flow comfortably 1.6 liters per minute to the analyzer. The fast loop flow should be a minimum of 6.8 liters (4 x 1.6).

Flow rates are generally proportional to pressure drop. If initial pressure drop of 3 psi can be tolerated, then the above flow rate can be doubled. Flow rates are generally inversely proportional to liquid viscosity.

We do not recommend using disposable microfiber elements with Fast Loop assemblies.