This element overview is designed to provide a brief snap shot of all our filter elements.

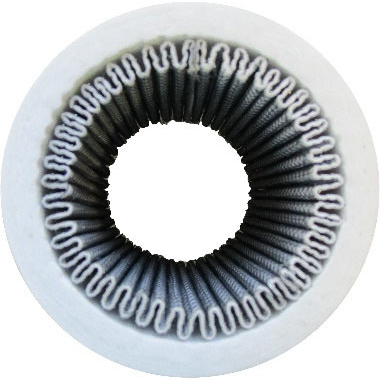

Coalescing

Our coalescing filter elements are completely disposable, made entirely from borosilicate glass microfiber. The coalescing elements have a two-layer structure, an inner particle capture-layer and an outer drainage layer. Liquid droplets remain mobile once captured, and travel through the fine-pored capture-layer, along the intersecting microfibers, growing in size as they progress. These coalesced droplets are transferred to the large-pored drainage layer from where they drain by gravity into the filter bowl. Coalescing elements should always flow from the inside to the outside of the element so that proper draining of liquids can occur. These elements will simultaneously collect liquids and particulates.

C Grade – Coalescing (Oil and Water Removal)

Elements are specifically designed for the removal of liquid aerosols and particulate from gases in both corrosive and non-corrosive applications. The C type element is constructed of two layers of borosilicate microfiber.

Typically Used In Our Point-of-Use Filters

Technical Information:

- Materials of Construction: Borosilicate Glass Microfiber with PVDF Fluorocarbon Resin Binder

- Type of Application: Coalescing – Instrumentation

- Maximum Temperature: 300ºF

- Appearance: Off-White Toasted Color

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30C | 40C | 50C | 60C | 70C | 80C |

Our 70C is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

CS Grade – Heavy Coalescing

Elements are designed for heavy coalescing, CNG, and vacuum pump exhaust. Good to 900°F.

Typically Used with Our High Flow 3/4” NPT Filter Housings and Above.

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with Silica Inorganic Resin

- Type of Application: Heavy Coalescing / CNG

- Maximum Temperature: 900ºF

- Appearance: White in Color

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30CS | 40CS | 50CS | 60CS | 70CS | 80CS |

Our 70CS is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

The 50CS is recommended for the coalescing of oils in vacuum pump exhaust applications.

CSX1 Grade – Exterior Caged for Added Burst Strength

These Elements are designed for heavy coalescing applications. Commonly used in CNG applications where added strength is needed due to heavy particulate loading and extremely contaminated coalesced oil. Good to 900°F .

Technical Information:

- Materials of Construction: Borosilicate Glass Microfiber with Silica Inorganic Resin with 304 SS Cage

- Type of Application: Heavy Coalescing / CNG

- Maximum Temperature: 900ºF

- Appearance: White in Color with exterior SS Cage

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30CSX1 | 40CSX1 | 50CSX1 | 60CSX1 | 70CSX1 | 80CSX1 |

Our 70CSX1 grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

All of our coalescing elements can be caged by adding suffix X1; including the C and RC Grades.

*X1 Caged on the outside only compatible for use with any of our standard filter housings.

CSX3 Grade – Interior and Exterior Cage for Added Burst Strength

These Elements are designed for heavy coalescing applications. Commonly used in CNG service where added strength is needed due to heavy particulate loading and extremely contaminated coalesced oil. Optional Exterior Cage only is designated by the suffix X1. Good to 900°F.

Technical Information:

- Materials of Construction: Borosilicate Glass Microfiber with Silica Inorganic Resin with 304 SS Cage

- Type of Application: Heavy Coalescing / CNG

- Maximum Temperature: 900ºF

- Appearance: White in Color with SS Cage

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. To Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30CSX3 | 40CSX3 | 50CSX3 | 60CSX3 | 70CSX3 | 80CSX3 |

Our 70CSX3 grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

All of our coalescing elements can be caged by adding suffix X3; including the C and RC Grades.

*X3 Caged inside and out are not compatible with our standard Aluminum or Brass housings.

RC Grade – Reinforced Coalescing for High Differential Pressure

Elements are designed for high pressure coalescing and/or systems with high differential pressure. These elements consist of a borosilicate glass inner layer sandwiched between two, rayon/phenolic layers. The reinforced inner/outer layers provide excellent strength.

Typically Used in Extreme Coalescing Service.

Technical Information:

- Materials of Construction: Glass Microfiber, Rayon/Phenolic

- Type of Application: High Differential Coalescing

- Maximum Temperature: 250ºF

- Appearance: Brown in Color

- Flow Direction: Inside to Outside

Efficiency at 0.3 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | N/A | N/A | N/A | RC | N/A |

Our RC grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

Dual Pleated Coalescing Series

Our DPCS elements incorporate an inner reinforced pleated microglass 3 micron pre-filter encapsulated with an outer microfiber glass coalescing layer. The pleats provide excellent dirt holding capacity, protecting the coalescing layer allowing it to drain liquids efficiently. This cartridge combines the pleated and coalescing elements into one package. We typically recommend this on our larger vessels which hold 2” diameter elements; i.e. 51-230 & 51-476 sizes.

Technical Information:

- Materials of Construction: Borosilicate Microfiber Glass with Silica Inorganic Resin; MicroGlass, Epoxy Coated Steel; PVC / Nylon End Caps

- Type of Application: Heavy Particulate and Coalescing

- Maximum Temperature: 300ºF

- Appearance: White in Color

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | 40DPCS | 50DPCS | 60DPCS | 70DPCS | N/A |

Our 70DPCS is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

Sintered Polyethylene (PEL) – Particle

Compressed air/gas applications: The PEL elements may be utilized as pre-coalescers or initial coarse filters in heavily contaminated systems. The 75-micron grade is recommended for this task since it exhibits the best flow curves, low initial DP.

Technical Information:

- Material of Construction: Virgin Polyethylene

- Type of Application: Coarse Coalescer

- Maximum Temperature: 212ºF

- Appearance: Bright White

- Flow Direction: Inside to Outside for Coalescing

- Standard Micron Sizes: 10, 25, 75, 100 & 250

PEL filter elements are constructed from virgin polyethylene (H.D.P.E.). The material is in powdered/granular form and then compressed into a sintered tube. This process allows the filter element to be free from foreign binders. Thus, the only compatibility issue is with polyethylene. No end caps or gaskets are necessary to seal the element into place. Axial compression is used to create a seal on the flat surface of the element. The PEL elements are naturally hydrophobic.

CA-800 Series – Coalescing Cartridges for Use in Onstream Housings

These coalescing cartridges were specifically designed for use in our SLH800 series filter housings. Ideal for compressed air/gas applications where a low pressure stainless steel housing is required.

Technical Information:

- Material of Construction: Borosilicate Glass Microfiber, Techbond ADH clear adhesive, 304 SS End Caps, Viton Grommets

- Type of Application: Particulate Removal

- Maximum Temperature: 180ºF

- Appearance: White Glass Microfiber with Silver Stainless; End Caps and Brown Viton Grommets

- Flow Direction: Inside to Out

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | N/A | 50CS | N/A | 70CS | N/A |

Our 70CS is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

Particulate / Emissions / Sample Conditioning

Environmental, Emissions, and Sample Conditioning filtration presents unique challenges due to the corrosive service, temperature and the analyzers’ need for a true, but clean stream. We offer the industry’s widest variety of borosilicate glass microfiber filter elements with binders to suit specific applications based on chemical compatibility.

Our high efficiency emission elements are 90% void space which provides greater surface area for particles to impinge on the individual fibers. This attribute is utilized throughout the depth of the filter expanding service life.

We have the ability to customize fiber size and binder blends to optimize filter performance for individual applications. Please consult our technical team with your specific needs so that we may suggest an optimal solution.

K Grade – Non-Reactive PVDF Binder

Elements are specified for particulate removal where corrosive gases are to be filtered as they provide excellent chemical resistance. They are also used when highly reactive gases are being analyzed since they exhibit very low levels of adsorption. The borosilicate glass microfiber provides relatively high flow rates with low pressure drops which is critical in analytical applications. The PVDF binder creates a non-reactive surface allowing for accurate sample analysis.

Typically Used with Our SS, PTFE & Kynar Sample Conditioning Products.

Technical Information:

- Materials of Construction: Borosilicate Glass Microfiber with PVDF Fluorocarbon Resin Binder

- Type of Application: Particulate Analytical, Emissions Testing, Sample conditioning

- Maximum Temperature: 300ºF

- Appearance: Off White Toasted Color

- Flow Direction: Typically Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30K | 40K | 50K | 60K | 70K | 80K |

Our 70K grade is recommended optimal filtration by providing high flow rates and long element life at peak efficiency.

K Grade – Selective Catalytic Reduction (SCR)

K Grade elements can be used for Selective Catalytic Reduction (SCR). By processing these elements in a special Acid Wash (AW) the elements can capture the excess ammonia that is introduced into the emission stream. This scrubbing is done by a chemical bond between the ammonia (NH3) and the acid washed (Phosphoric) filter elements, thus protecting sensitive equipment.

S Grade – High Temperature Silica Inorganic Resin

S Grade elements are completely inorganic and specifically designed to be used in automotive and diesel particulate filter applications where sampling is above 300°F (150°C). These elements have the ability to function up to 900°F (480°C).

Typically Used with Our SS Sample Conditioning Filters and H Series Heatable Housings.

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with Silica; Inorganic Resin Binder

- Type of Application: Emissions / Stack Gas

- Maximum Temperature: 900ºF

- Appearance: White in Color

- Flow Direction: Typically Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30S | 40S | 50S | 60S | 70S | 80S |

Our 70S grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

S Grade – Selective Catalytic Reduction (SCR)

S Grade elements can be used for Selective Catalytic Reduction (SCR). By processing these elements in a special Acid Wash (AW) the elements can capture the excess ammonia that is introduced into the emission stream. This scrubbing is done by a chemical bond between the ammonia (NH3) and the acid washed (Phosphoric) filter elements, thus protecting sensitive equipment.

ET Grade – PVDF Proprietary for Automotive Emission Testing

These elements are hydrocarbon-free filters developed to remove particulate for automotive/diesel emission testing up to 400F .

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with PVDF; Proprietary

- Type of Application: Automotive Emission Testing

- Maximum Temperature: 400ºF

- Appearance: Off-White Toasted Color

- Flow Direction: Typically Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30ET | 40ET | 50ET | 60ET | 70ET | 80ET |

Our 70ET grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

RPT Grade – Hydrocarbon Free Emission Test Filters

RPT Grade elements are constructed of a proprietary blend of microfiber glass and resin binders which virtually eliminate initial hydrocarbon content. This feature provides fast initial response times for emission analysis. These elements have the ability to function up to 650°F (342°C).

Typically Used with Our SS Sample Conditioning Filters and H Series Heatable Housings.

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with proprietary resin blend

- Type of Application: Automotive/Diesel Emissions

- Maximum Temperature: 650ºF

- Appearance: White in Color

- Flow Direction: Typically, Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | N/A | 50RPT | 60RPT | 70RPT | N/A |

Our 60RPT grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

S21-R Grade – Diesel Emissions with Heavy Particulate

The S21-R Type elements are constructed with a loose inner layer designed to provide more surface area thus capturing diesel particles without blinding off the element. The final stage of filtration is accomplished by the outside layer of the element.

Typically Used with Our H Series Tie Rod Heatable Housings.

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with Silica Inorganic Resin Binder

- Type of Application: Heavy Diesel Emissions

- Maximum Temperature: 900ºF

- Appearance: White in Color

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | N/A | 50S21-R | 60S21-R | 70S21-R | 80S21-R |

Our 70S21-R grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

R Grade – Heavy Particulate Filtration

Elements are designed for heavy loading particulate filtration. They are typically used in remote compressed gas service since they are able to handle a higher differential pressure than other disposable elements. These elements are constructed of wrapped rayon fibers with a phenolic resin binder.

Typically Used in Extreme Particulate Service.

Technical Information

- Materials of Construction: Rayon/Phenolic

- Type of Application: High Differential Particulate

- Maximum Temperature: 250ºF

- Appearance: Brown in Color

- Flow Direction: Outside to Inside

Efficiency at 0.3 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| N/A | N/A | N/A | N/A | R | N/A |

Our R grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

Epoxy Grade – OEM Particulate Filtration

These elements are suitable for all particulate removal applications in non-corrosive gases. These are the most economical particulate filters we offer and are typically utilized in OEM applications.

Typically Used in OEM Applications.

Technical Information

- Materials of Construction: Borosilicate Glass Microfiber with Epoxy Ester Resin

- Type of Application: Particulate Only

- Maximum Temperature: 300ºF

- Appearance: Light Manilla Color

- Flow Direction: Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95% | +75% |

|---|---|---|---|---|---|

| 30 | 40 | 50 | 60 | 70 | 80 |

Our 70 grade is recommended for optimal filtration by providing high flow rates and long element life at peak efficiency.

Particulate Elements

We offer five types of particulate elements which provide the correct solution for your applications. For instrument air and gaseous service we provide pleated, five-layer stainless steel, stainless steel screen, and sintered polyethylene elements. For sample conditioning, emission testing and environmental service we offer a variety of disposable microfiber elements as well chemical resistance sintered PTFE elements.

Pleated Microglass – Heavy Particulate Filtration – TRE Version

TRE Pleated elements are designed to securely thread into our 300 series Aluminum housings. The Pleated elements are used as pre-filters for coalescers where solid contaminants are present. Our 3 micron pleated elements are recommended as post filters on desiccant type dryers to contain dust.

Technical Information:

- Material of Construction: MicroGlass, Epoxy Coated Steel, Nylon, Viton – Larger units contain 304SS Core

- Type of Application: Particulate Removal

- Maximum Temperature: 212ºF / 300ºF (Dependent on Size)

- Appearance: Pleated White Microglass with Epoxy Coated Steel Screen

- Flow Direction: Outside to Inside

- Micron Sizes: 03, 10, 25

Pleated Microglass – Heavy Particulate Filtration – DOE Version

DOE Pleated elements are designed to securely fit our 100 series Stainless Steel housings giving our customers infield flexibility to switch between a variety of elements without changing housings. The Pleated elements are used as pre-filters for coalescers where solid contaminants are present. Our 3 micron pleated elements are recommended as post filters on desiccant type dryers to contain dust.

Technical Information

- Material of Construction: MicroGlass, Epoxy Coated Steel, Nylon, Viton – Larger units contain 304SS Core

- Type of Application: Particulate Removal

- Maximum Temperature: 212ºF / 300ºF (Dependent on Size)

- Appearance: Pleated White Microglass with Epoxy Coated Steel Screen

- Flow Direction: Outside to Inside

- Micron Sizes: 03, 10, 25

Pleated Cellulose

The 12-48-10PLCL is specially designed to be used in our low cost 1/8” and ¼” plastic and aluminum filters (705N – 315A). United Filtration’s pleated Cellulose Filters, sometimes referred to as Paper Filters, offer a larger surface area for particulate laden air/gas applications. The pleats increase surface area thus extending filter life and lowering the initial clean dry PSID.

Technical Information

- Material of Construction: Cellulose, Epoxy, SS Support Core, Corrosion Resistant Aluminum End Caps, Buna N Seals, Black Nylon Stem

- Type of Application: Particulate Removal

- Maximum Temperature: 200ºF

- Appearance: Pleated Tan Cellulose with Silver Aluminum; End Caps and Black threaded Stem

- Flow Direction: Outside to Inside

- Micron Sizes: 10, 20

Media selection should be based upon required cleanliness and other application parameters. Pleated Cellulose filters offer a low-cost solution for heavy particulate laden applications where bulk removal is desired. They should not be used as a final scrub in sensitive systems.

Pleated Stainless Steel

DOE Pleated Stainless Steel elements are designed to securely fit our 100 series Stainless Steel housings giving our customers infield flexibility to switch between a variety of elements without changing housings. The Pleated stainless-steel elements provide excellent strength, and are ideal for a variety of demanding applications where disposable elements have specific limitations.

Technical Information

- Materials of Construction: 304 Stainless Steel, Viton

- Type of Application: Remove Particles from Gaseous Stream

- Maximum Temperature: 400ºF

- Appearance: Pleated SS Mesh with Brown Viton Seals

- Flow Direction: Outside to Inside

- Micron Sizes: 5, 10, 25, 50, 75, 100, 150, 200 (other micron sizes available – special order)

Five-Layer Stainless Steel

Stainless Steel elements are recommended for filtration of heavily contaminated gases, liquids, polymers, and steam, since they are re-cleanable by back-flushing or ultrasonic cleaning. The elements consist of five layers of precision-woven 316L stainless steel mesh formed into cylinders and sintered together.

Technical Information

- Material of Construction: Five Layer 316L Stainless Steel with PTFE or Viton End Seals (Pictured with PTFE)

- Type of Application: Sample Conditioning, Fast Loop, Steam, and Liquid

- Maximum Temperature: 1000ºF (without seals)

- Appearance: 316L Stainless Steel

- Flow Direction: Both

- Micron Sizes: 0.5, 01, 03, 10, 25, 50, 100, and 200

We offer eight standard grades of filtration which fit our Headline Filters line of housings, as well as other proprietary brands. Micron Sizes: 0.5, 1, 3, 10, 25, 50,100, 200 at 98% efficiency in gases and liquids. Grade 25 (25 micron) is widely used to protect pumps and valves while grade 03 (3 micron) is recommended for removal of pipe scale from steam. The SS Elements are environmentally friendly because they are durable and non-absorbent, they can be backwashed, cleaned and reused, thus eliminating a major disposal headache.

Sintered Polyethylene (PEL) – Particulate Removal

Compressed air/gas applications: PEL elements are a cost effective robust particle filter for point-of-use service. These filters can handle a high differential before collapsing.

Technical Information

- Material of Construction: Virgin Polyethylene

- Type of Application: Particle Filtration

- Maximum Temperature: 212ºF

- Appearance: Bright White

- Flow Direction: Outside to Inside for Particulate

- Micron Sizes: 10, 25, 75, & 100

PEL filter elements are constructed from virgin polyethylene (H.D.P.E.). The material is in powdered/granular form and then compressed into a sintered tube. This process allows the filter element to be free from foreign binders. Thus, the only compatibility issue is with polyethylene. No end caps or gaskets are necessary to seal the element into place. Axial compression is used to create a seal on the flat surface of the element. The PEL elements are naturally hydrophobic.

Stainless Steel Single Layer Screen

These Stainless Steel single layer mesh screens are ideal for the removal of bulk contamination in corrosive streams and desiccant powder after dryers. They are primarily used as pre-filters in both gaseous and liquid applications.

Their low cost allows them to be “disposable” in many corrosive or heavily contaminated operations.

Technical Information

- Material of Construction: Single Layer 304 Stainless Steel

- Type of Application: Pre-Filter for Particulate, Diffuser in Liquid Service

- Maximum Temperature: 400ºF

- Appearance: 304 Stainless Steel

- Flow Direction: Outside to Inside

- Micron Sizes: 10, 25, 50, 75, 100, 200, and 500 (other sizes availble upon request)

The LSS is a single layer precision woven screen that offers moderate filtration efficiency. Because of the small diameter and short length, these elements do not require a support core.

For Capillary Well Service our 50 and 100-micron SS filter screens offer exceptional filtration while still providing high flow rates for such a compact design. The element’s small diameter eliminates the need for a collapse core thus increasing true filtration area and providing longer element life.

PTFE – Corrosive Service

PTFE filter elements are recommended for compressed gas where our microfiber and stainless steel elements are unsuitable. Made from pure PTFE sintered (under pressure) into cylinders. The “PT” elements have outstanding chemical compatibility and extreme hydrophobic characteristics. No end caps or gasket materials are required for a positive seal.

Typically Used with Our PTFE & Kynar Housings.

Technical Information

- Material of Construction: PTFE

- Type of Application: Particulate Filtration in Corrosive Service

- Maximum Temperature: 400ºF

- Appearance: Pure White

- Flow Direction: Typically Outside to Inside

- Micron Sizes: 03, 25

PTFE Elements are typically used to eliminate particulates, but also can remove small amounts of liquids, because of their pore structure, and hydrophobic characteristics.

Vapor Adsorption Cartridges

Vapor Adsorption Cartridges are designed to selectively remove vapors from air and other gases by passing the stream through a bed of adsorbent granules. The most common applications are activated carbon (CC) for hydrocarbon removal and silica gel (SG) for water vapor removal. These are considered polishing or final trace filters and are typically only specified in the most critical applications.

Adsorption Cartridges

Vapor Adsorption Cartridges come in two basic formats both utilizing a high efficiency borosilicate microfiber disposable element which will capture any adsorbent material thus protecting the downstream system. It is important to protect the adsorption cartridge with pre-filters so that the granules have full contact with the vapors that need to be extracted. Contact time is also critical so that the flow rate should be minimal.

Technical Information

- Materials of Construction: Borosilicate Microfiber Glass Element with Black Nylon End Caps

- Type of Application: Vapor Adsorption

- Maximum Temperature: 212ºF

- Appearance: Black Nylon End Caps with a White Outer Element

- Flow Direction: Both

Adsorption Cartridges are designed to fit all standard size housings. Our Stainless Steel housings accept cartridges designated with the suffix “TS” (i.e. 25-64-CC-TS) and our Aluminum and Plastic series accept cartridges designated with the prefix “TRE” (i.e. TRE25-64-CC).

[table “30” not found /]We also offer Adsorption Dryer Housings (ADS) and Adsorption Columns (IACH & IAAH) which are essentially vessels packed with loose refillable adsorbent. Since there is much greater volume of media within the vessel these are specified for systems with high flow rates.

Liquid Elements

Liquid filter elements are designed to capture particles in a liquid stream. We offer two basic types of filter cartridges; melt blown depth filter and pleated cartridges. Polyspun (melt blown) which are an economical solution for non-critical and basic applications. Our pleated line encompasses polypropylene, stainless steel, and microglass. These three options allow UFS to provide a variety of efficiencies and service life across a full spectrum of applications. Which include but are not limited to fuel, chemical processing, pharmaceutical, and resins.

Our liquid elements are manufactured to industry standards allowing them to fit in other proprietary filter housings, as well as our Onstream SLH series of assemblies. All liquid elements are designed for standard sizes (2.50” OD). Available in lengths of 4.875”, 9.75”, 19.875”, & 29.875”.

Spun Polypropylene – Liquid Applications

Our Polyspun filter cartridges are nominally rated 100% pure polypropylene filter cartridges. A high performance process, using very fine fibers, which build up producing spun bonded layers, give the filter its depth. This process results in a cartridge with excellent pore size consistency and very high void volumes. The outer layers contain different graded pore sizes, which act as pre-filtration by removing larger particles from the stream, leaving smaller particles to be trapped by the fine fibers of the inner layer.

Technical Information

- Materials of Construction: Spun Polypropylene

- Type of Application: Remove Particles from Liquid Stream

- Maximum Temperature: 160ºF

- Appearance: White Polypropylene Microfiber

- Flow Direction: Outside to Inside

- Micron Sizes: 01, 05, 10, 25, 50, 75, 100, 150

The use of very fine fibers – typically between 1 and 5 micron – creates many more pores than is possible with large fiber which results in open volumes in excess of 65% which in turn provides longer service life.

Pleated Polypropylene – Liquid Applications

These cartridges are suitable for all particulate removal applications in non-corrosive gases and liquids. The coarsest grade that will adequately protect the application should be chosen, as this will result in the most economical solution to the contamination problem.

Technical Information

- Materials of Construction: Polypropylene, EPDM

- Type of Application: Remove Particles from Liquid Stream

- Maximum Temperature: 180ºF

- Appearance: White Pleated Polypropylene with Polypropylene Cage, Black EPDM Seals

- Flow Direction: Outside to Inside

- Micron Sizes: 01, 10, 25, 50, 75

Micron sizes available are 01, 10, 25, 50 and 75.

Pleated Stainless Steel – Liquid Applications

Pleated stainless steel elements provide excellent strength, and are ideal for a variety of demanding applications where disposable elements have specific limitations. They fit our Onstream SLH housings and other proprietary brands.

Technical Information

- Materials of Construction: 304 Stainless Steel, Viton

- Type of Application: Remove Particles from Liquid Stream

- Maximum Temperature: 400ºF

- Appearance: Pleated SS Mesh with Brown Viton Seals

- Flow Direction: Outside to Inside

- Micron Sizes: 5, 10, 25, 50, 75, 100, 150, 200 (other microns available – special order)

Liquid Elements for UFS / Headline Products

Liquid filter elements our designed to capture particles in a liquid stream. We offer two basic types of filters that fit our standard UFS/Headline filter housings with tie rods; Five-Layer Stainless Steel Mesh and Pleated MicroGlass elements. These two options allow UFS to provide a variety of efficiencies and service life across a full spectrum of critical applications. By utilizing a double opened ended filter element we have the ability to install these two types of elements into our standard range which allow us to provide solutions in all sorts of environments even at high temperatures and pressures up to 10,000 psig.

Five-Layer Stainless Steel

Stainless Steel elements are recommended for filtration of heavily contaminated liquids, polymers, and steam, since they are re-cleanable by back-flushing or ultrasonic cleaning. The elements consist of five layers of precision-woven 316L stainless steel mesh formed into cylinders and sintered together.

Technical Information

- Material of Construction: Five Layer 316L Stainless Steel with PTFE or Viton End Seals (Pictured with PTFE)

- Type of Application: Sample Conditioning, Fast Loop, Steam, and Liquid

- Maximum Temperature: 400ºF

- Appearance: 316L Stainless Steel

- Flow Direction: Both

- Micron Sizes: 01, 03, 10, 25, 50, 100, and 200

We offer seven standard grades of filtration, which fit our Headline Filters line of housings, as well as other proprietary brands. Micron Sizes: 0.5, 1, 3, 10, 25, 50,100, 200. Grade 25 (25 micron) is widely used to protect pumps and valves while grade 03 (3 micron) is recommended for removal of pipe scale from steam. The SS Elements are environmentally friendly because they are durable and non-absorbent, they can be backwashed, cleaned and reused, thus eliminating a major disposal headache.

Stainless Steel Single Layer Screen

Ideal in liquid applications where particulate removal is needed. Used across a wide variety of applications these low cost filters are the perfect solution as prefilters or in corrosive heavily contaminated streams.

Technical Information

- Material of Construction: Single Layer 304 Stainless Steel

- Type of Application: Pre-Filter for Particulate, Diffuser in Liquid Service

- Maximum Temperature: 400ºF

- Appearance: 304 Stainless Steel

- Flow Direction: Outside to Inside

- Micron Sizes: 10, 25, 50, 75, 100, 200, and 500 (other sizes available upon request)

The LSS is a single layer precision woven screen that offers moderate filtration efficiency. Because of the small diameter and short length, these elements do not require a support core.

For Capillary Well Service our 50 and 100-micron SS filter screens offer exceptional filtration while still providing high flow rates for such a compact design. The element’s small diameter eliminates the need for a collapse core thus increasing true filtration area and providing longer element life.

PTFE – Corrosive Service

PTFE filter elements are recommended for liquid filtration where our microfiber and stainless steel elements are unsuitable. Made from pure PTFE sintered (under pressure) into cylinders. The “PT” elements have outstanding chemical compatibility and extreme hydrophobic characteristics, which make them ideal for liquid sampling applications.

No end caps or gasket materials are required for a positive seal.

Typically Used with Our PTFE & Kynar Housings.

Technical Information

- Material of Construction: PTFE

- Type of Application: Particulate Filtration in Corrosive Service

- Maximum Temperature: 400ºF

- Appearance: Pure White

- Flow Direction: Typically Outside to Inside

- Micron Sizes: 03, 25

PTFE Elements are typically used to eliminate particulates, but also can remove small amounts of liquids, because of their pore structure, and hydrophobic characteristics.

Sintered Polyethylene (PEL) – Particle Removal in Liquid

Slight pressure will force liquid through the element while at the same time repelling any dirt “particulate” which is encapsulated in the water. The element uses two filtration techniques, surface area and depth. Typical flow direction is out to in, since dirt is visible on the outside surface area and the outer diameter is larger for increased surface filtration. The elements may be back flushed in place, or cleaned ultrasonically, however their low cost makes it economical to dispose of.

Technical Information

- Material of Construction: Virgin Polyethylene

- Type of Application: Particle Filtration in Liquid

- Maximum Temperature: 212ºF

- Appearance: Bright White

- Flow Direction: Either Direction

- Micron Sizes: 10, 25, 75, & 100

PEL filter elements are constructed from virgin polyethylene (H.D.P.E.). The material is in powdered/granular form and then compressed into a sintered tube. This process allows the filter element to be free from foreign binders. Thus, the only compatibility issue is with polyethylene. No end caps or gaskets are necessary to seal the element into place. Axial compression is used to create a seal on the flat surface of the element. The PEL elements are naturally hydrophobic.

Pleated MicroGlass – Liquid Applications

These elements are specifically designed to be used in our 150/160 high pressure filter housings where high flow rates and high efficiency filtration is required. The inner spiral wound 304 Stainless Steel support core and reinforced pleats provide high flows along with added durability.

Technical Information

- Materials of Construction: Pleated Glass Microfiber; Expoxy Coated Steel Reinforced Screen; Inner 304 Stainless Steel Support Core; PVC End Caps; Viton O-Rings

- Type of Application: Remove Particles from Liquid Stream

- Maximum Temperature: 140ºF

- Appearance: Perforated Metal with Black End Caps

- Flow Direction: Outside to Inside

- Micron Sizes: 03, 10, & 25

Micron Sizes Available: 03, 10 & 25

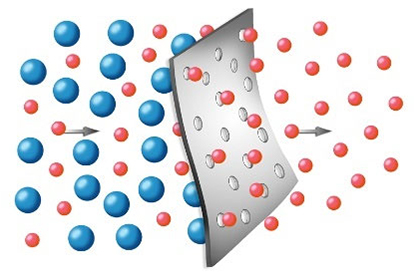

Membrane Separators

The ultimate filter for removing liquids is a PTFE based membrane. These membranes allow gases to pass while blocking larger liquid molecules. We offer a comprehensive line of membrane separator holders that are used to protect analyzers. We recommend that a coalescing filter be installed upstream of a membrane to protect it from particulates and flooding.

Guardian Membrane Filters

For absolute liquid removal in extremely low flow applications we recommend our Guardian Membrane Separators. These units are designed for critical point-of-use service. The actual membrane is a flat disc that is sandwiched between two plates. The gas flow permeates the membrane while liquid is blocked and runs off into a drain. Our membranes are interchangeable with other proprietary brands.

Technical Information

- Material of Construction: PTFE Membrane

- Type of Application: Analyzer Protection

- Maximum Temperature: 300ºF

- Appearance: White Disc

- Maximum Flow Rate: 18 LPM

- Micron Sizes: M1HG – 0.1 Absolute (Low Flow); M2HG – 0.8 Absolute (High Flow)

PTFE Membranes are solely utilized in our GMS Series of Filters. We do not offer sizes to fit our complete filter housing range. Maximum flow rate on our largest membrane is 18 LPM.

Guardian Membrane Environmental Filters

We also offer a full range of point-of-use disc and syringe filters for environmental, analytical, lab, and medical markets. We stock a full range of options for the most common applications. The GME series of membranes provide complete filtration for ultra-critical low flow sample conditioning.

Technical Information

- Membrane Material Offerings: PES, PTFE, Nylon, Glass Fiber, Cellulose Acetate

- Body Material: Polypropylene

- Micron Sizes Available: 0.22 to 10 Micron

- Connections: Stepped Barbs & Luer Lok

The GME Series are available in Sterile and Non-Sterile form.

Steam Elements

We offer two basic types of Steam Elements; Disposable Coalescing Borosilicate Microfiber and Five-Layered Stainless Steel elements for particulate and bulk liquid removal. Both types of elements are available in sizes to fit OEM steam sterilizer filter systems. It is important to have a condensate drain to immediately evacuate any collective liquids.

Disposable Steam Elements – Grade ZZ

Our 37/59-460-70ZZ OEM retro-fit steam elements are constructed of 100% borosilicate glass microfiber providing up to 95% efficiency against 0.01 microns. We utilize a PVDF binder which allows the element to function at temperatures up to 300°F (150°C). It is important to note that the 70ZZ elements should be changed-out every six weeks, and that solid particles will shorten their service life by reducing surface area which is needed to remove liquid droplets. A condensate drain is a mandatory accessory on a steam filter, ensuring immediate liquid removal. Every application is unique and must be monitored to ensure proper change out frequency. The particles will also increase the pressure drop, which can lead to element rupture. For added security, the element can be caged with inner and outer stainless steel support cores designated by a suffix of “X3”.

Technical Information

- Materials of Construction: Borosilicate Microfiber Glass with PVDF Resin Binder

- Type of Application: Sterile Air Applications

- Maximum Temperature: 275ºF

- Appearance: Off-White Toasted Color

- Flow Direction: Inside to Outside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95%* | +75% |

|---|---|---|---|---|---|

| N/A | N/A | N/A | N/A | 70ZZ | N/A |

Five-Layer Stainless Steel for Steam Filtration

Stainless Steel elements are ideal for removing particulate from steam and can be used as a bulk liquid knockout. The elements’ five layers act as a coarse “coalescing” filter. We recommend the 3 micron as a good starting point for steam filtration and our SS-51-460-03T element retro fits into OEM housings.

Technical Information

- Material of Construction: Five Layer 316L Stainless Steel with PTFE

- Type of Application: Steam

- Maximum Temperture: 400ºF

- Appearance: 316L Stainless Steel

- Flow Direction: Both

- Micron Sizes: 01, 03, 10, 25, 50, 100, and 200

The 3 micron is recommended for removal of pipe scale from steam. The SS Elements are environmentally friendly because they are durable and non-absorbent, they can be backwashed, cleaned and reused, thus eliminating a major disposal headache.

L Grade – Sterile Air

These elements are bonded with a hydrophobic binder making them ideal for use where steam sterilization is required. The silicone binder prevents the pores from being filled with condensate, which can encourage bacterial growth. Maximum recommended steam pressure is 60 PSIG.

Technical Information

- Binder Type: Borosilicate Glass Microfiber with Silicone Resin

- Type of Application: Sterile Air Applications

- Maximum Temperature: 300ºF

- Appearance: White in Color

- Flow Direction: Outside to Inside

Efficiency at 0.01 microns. Suffix Grade designation:

| 99.99998% | 99.9999% | +99.99% | +99.5% | +95%* | +75% |

|---|---|---|---|---|---|

| N/A | 40L | N/A | N/A | N/A | N/A |

In air applications the 40L element must be protected by two coalescing (70C and 50C) pre-filters, which remove solids, and any liquids within the system. The 40L element remains dry. The 40L element can be independently steam sterilized in an air system to discourage bacterial growth.

Custom Solution Elements

We have the ability and desire to offer custom filter elements to meet our clients demanding applications. By partnering with our vendors and customers we can deliver innovations that turn product ideas into solutions.

Following are a few examples of Custom Solution elements that are now the norm:

Natural Gas Vehicle – Coalescing

Custom Coalescing NGV filters that are private labeled for the NGV aftermarket. Provide us your specifications and we will deliver samples for your approval, then we handle your stocking and packaging requirements.

Attributes:

- Private label

- Meets Customer Validation Requirements

- Custom Size Connections, Per Client Specs for Wide Variety of Markets

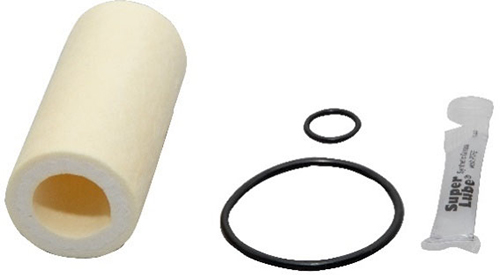

High Pressure Compressed Gas – Coalescing

Double O-Ring / spring loaded elements for CNG compressor station service. A positive/secure fit for high velocity / high vibration service. Our UHPC5-SL accepts the SL-38-172-RCX3 element that is pictured. Built for extremely harsh service using proven material.

Attributes:

- Reinforced

- Positive Sealing

- Built-in Pressure Relief

- High Efficiency

Bronze Filter Elements

Bronze filter elements to fit our brass filter housings for oxygen service.

For Critical Service specify our B360-OS (Oxygen Service) series of all Brass / Bronze Material.

Attributes:

- Oxygen Service

- Critical Clean Applications

- Laser Service

- Impact Resistant, Self-Supporting Structure

Custom Disposable Elements

Bronze element adaptor with non-shedding filter element for oxygen service and laser applications (Pictured).

Attributes:

- Turn Key Replacement Elements

- Tailor Made to Meet your Requirements

- Innovation, Cost Effective, User Friendly Designs